We Have a Passion

for Building Great Works!

We challenge the norms and deliver excellence with every project.

Delivering Innovative Solutions

for Complex Heavy Civil Projects

We build tomorrow’s future, today.

Groundbreaking Precision

Beneath the Surface

We excel in delivering foundations that ensure the stability of critical structures.

Great Teams

Build Great Works

Teamwork fuels our passion to deliver innovative solutions.

For more than 70 years,

our focus on innovation and technology has allowed us to evolve from a small bridge and concrete company to a nationally-recognized, heavy-civil construction company.

Markets We Serve

We pride ourselves on our expertise in a multitude of projects spanning across various markets. Our diverse skill set and experience positions us as a versatile and reliable partner. Our capability in handling complex structures and challenging environments speaks volumes about our team’s commitment to excellence and our ability to deliver top-notch infrastructure solutions.

We build more than just roads and railways; we create the arteries of progress, connecting communities to opportunities and a sustainable future. Our transportation projects are designed to be resilient and efficient, embodying innovation and shaping a more accessible, interconnected world.

We excel in dam construction and rehabilitation, combining a deep understanding of complex engineering with value-added solutions. We focus on ensuring each dam project is durable, safe, and resilient, reflecting our commitment to creating lasting, reliable infrastructure.

We specialize in ports and marine infrastructure, capable of handling the unique challenges of these environments. Our focus is on constructing, rehabilitating, and maintaining durable marine structures, ensuring they are resilient against natural forces and provide reliable connectivity.

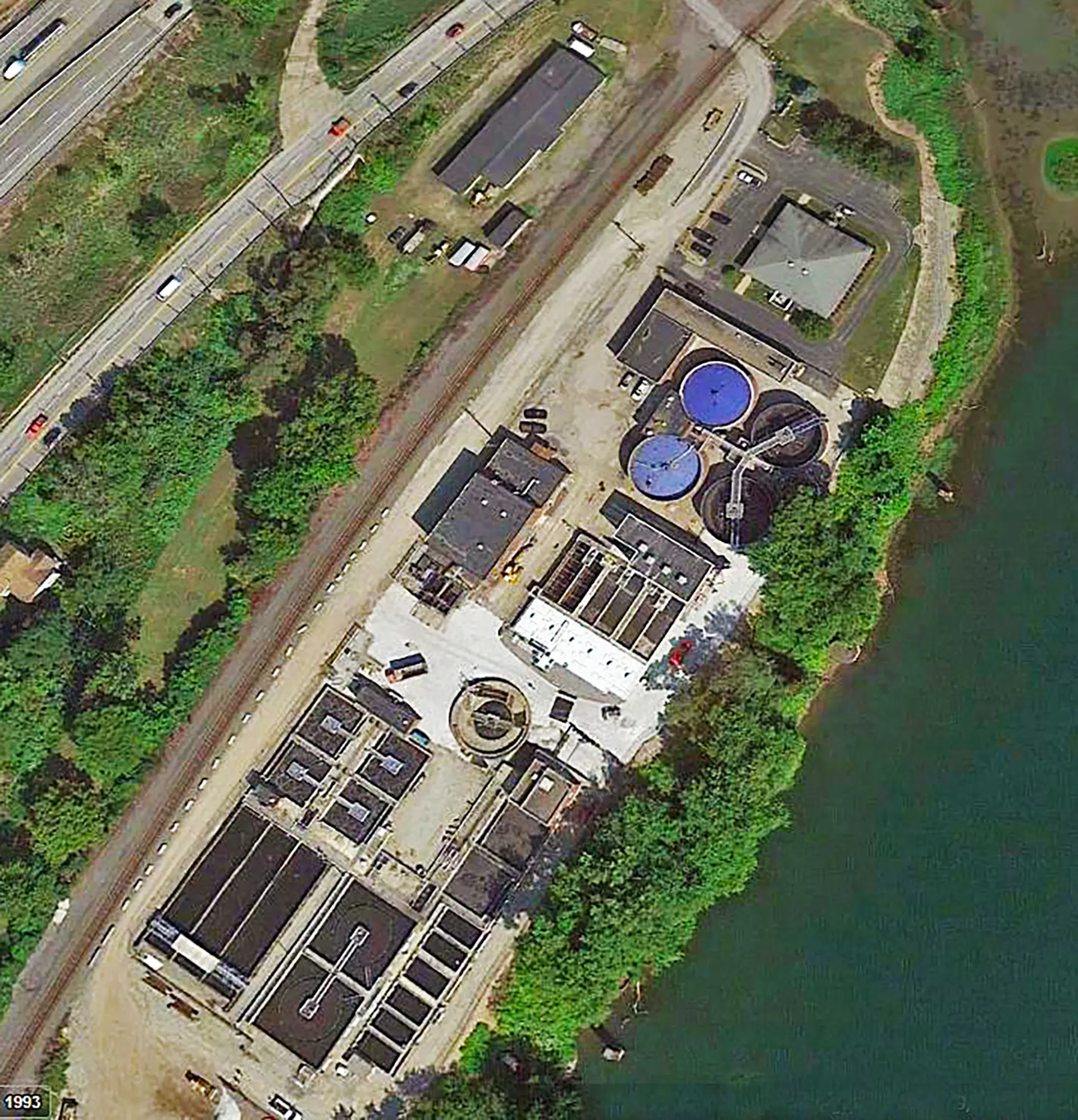

We specialize in geotechnical foundation work for the industrial sector, including projects for oil and gas plants and wastewater treatment facilities. Our expertise covers a wide range of techniques such as piling, micropiles, caissons, drilled shafts, and grouting, demonstrating our commitment to building strong, environmentally sound foundations for critical energy infrastructure.

We specialize in innovative foundation solutions for the energy industry, emphasizing structural integrity and environmental adaptability. Our approach caters to the unique needs of power facilities, ensuring safety and functionality. We excel in flexible ground improvement and deep foundation techniques, suitable for diverse locations, from urban to remote areas.

We excel in providing ground improvement solutions for commercial structures, ranging from high-rise buildings to modern office spaces. Our focus on deep foundation systems ensures long-term stability and security.

Brayman Capabilities

We specialize in delivering top-tier services in complex heavy civil infrastructure and deep foundation drilling and grouting. Our commitment to excellence and innovation positions us as a leader in creating robust and sustainable infrastructure solutions, rooted by our extensive experience and technical know-how.

Complex Heavy Civil Infrastructure

- Highway/Rail Bridge Construction/Rehabilitation

- Elevated Concrete Structures

- Locks and Dams

- Industrial Facilities

- Marine Construction

Deep Foundation Drilling & Grouting

- High Capacity Dam Anchors

- Secant / Tangent Walls

- Earth Retention

- Retaining Walls / Sound Walls

- Cofferdams / River Mooring Cells

- Support of Excavation (SOE)

- Drilled Shafts

- Micropiles

- Specialty Grouting / Instrumentation

- Soil Nailing / Shotcrete

- Pre-Drilled / Driven Piles

- Augercast Piles

Innovation

Brayman Construction leads the industry by boldly redefining construction, merging the strength of tradition with the power of technology. We don't just build structures; we set new benchmarks for excellence, pioneering innovative methods that transform every project we undertake.

Accelerated Bridge Projects

We are revolutionizing bridge construction with speed and precision. Our advanced techniques and prefabricated components slash traditional timelines, turning months into days, minimizing disruption, and delivering unmatched efficiency.

High Tech Partnerships

We're not just participants; we're leaders in innovation. We are dedicated to fostering partnerships that drive innovation, setting new standards in the construction industry and advancing technological integration.

Specialty Tools & Equipment

We don't just use tools; we master them. We maintain a diverse fleet ensuring peak performance, optimum resale value, and immediate availability for enhanced control and cost-effectiveness.

Industry Leading Construction Technique

We don't follow trends; we set them. We leverage the most advanced construction methods, ensuring each project is a testament to our commitment to innovation, quality, and successful completion.

Engineering Great Works with a Passion for Innovation

Brayman has expertise in a wide variety of projects including large scale complex bridges, deep foundation, marine and dam construction and rehabilitation, complex and heavy steel erection and rehabilitation, and demolition services. Our team carefully manages every aspect of every project, collaborating to provide inclusive and innovative design-build construction solutions while maintaining the highest standard of safety and customer service.

Brayman Careers

Brayman is seeking high-energy, motivated professionals looking to fulfill their passion in a progressive and fast-paced environment. We’re about being driven, innovative and creative.

STAY INFORMED

Explore the latest news and updates from Brayman Construction, where progress and innovation are always making headlines

Blog title heading will go here

Pittsburgh Robotics Network Names New Board Members

The Pittsburgh Robotics Network, a nonprofit organization dedicated to fostering innovation and growth for the southwest Pennsylvania region’s robotics cluster, yesterday announced changes to its board of directors and executive officers. Jorgen Pedersen has stepped in as the new board president, and Stephen Muck is now secretary.

Brayman's Feature Article on Embracing Diversity Graces the Cover of ADSC Foundation Drilling Magazine's Women In Construction Special Edition

Brayman salutes the hardworking women who are an integral part of our industry. From the job site to the office, their skills and contributions make a significant impact every day. Thank you to all the incredible women on #TeamBrayman for your dedication and expertise.

Learn more about the incredible women at Brayman in the below special edition ADSC feature article:

Brayman Construction And Trumbull Corporation Celebrate OSHA Partnership Signing For The Bayfront Parkway Improvement Project In Erie, PA

Brayman Construction and Trumbull Corporation are proud to announce a five-year Occupational Safety and Health Administration (OSHA) Strategic Partnership for the Bayfront Parkway Improvement Project in Erie, PA. This is the longest OSHA Partnership in Erie’s history, reflecting a strong commitment to workplace safety and health.

The goals of this partnership include reducing the total number of days away from work injury and illness cases by 3%, controlling workplace hazards by assisting contractors with the implementation of an effective safety and health management system, conduct weekly self-inspections to reduce exposure of workers to safety and health hazards, and to maintain a continuous dialog that support various safety and health campaigns/initiatives.

“At Brayman, safety is not just a policy; it’s our way of life. This partnership with OSHA and Trumbull Corporation reinforces our long-standing dedication to ensuring the highest safety standards,” said Stephen Muck, Chairman and CEO of Brayman Construction.

Mark Gentile, President of Trumbull Corporation, added, “Our partnership with Brayman Construction has been built over several successful projects, each reinforcing our shared commitment to delivering a safe project. This partnership with OSHA, is another step in our collaborative journey, reflecting Safety as a shared core value, in every aspect of our work.”

“Securing an OSHA Strategic Partnership reflects our continual efforts to lead the industry in safety practices,” stated Angela Ravenscroft, Corporate Safety Director at Brayman Construction. “This achievement is another milestone in our ongoing mission to provide a safe working environment for everyone.”

Christopher Snedden, Assistant Area Director for OSHA stated, “Anytime OSHA and responsible contractors from the private sector can work together to minimize hazards in the workplace and decrease the number of injuries, the result is always positive. We commend Brayman Construction and Trumbull Corporation for taking a proactive approach in prioritizing safety and committing to ensuring safe working conditions.”

The Bayfront Parkway Improvement Project, valued at $111.7 million, aims to strengthen the connectivity within the city of Erie by enhancing accessibility and safety for all its users. This project is not just an infrastructural development; it’s a step towards a safer, more connected community.

About Trumbull Corporation:

Trumbull Corporation is an award-winning industry leader in heavy civil construction, having built hundreds of bridges, highway projects, tunnels, excavation, locks, dams, well pad construction, pipeline installation, and utilities throughout the Mid-Atlantic region. Our world-class team is known for taking extra measures to ensure our work is thorough and accurate.

About OSHA:

In 1970, the United States Congress and President Richard Nixon created the Occupational Safety and Health Administration (OSHA), a national public health agency dedicated to the basic proposition that no worker should have to choose between their life and their job. The OSHA law makes it clear that the right to a safe workplace is a basic human right. Together with our state partners, OSHA has tackled fatal safety hazards and health risks. We have established common sense standards and enforced the law against those who put workers at risk. Our standards, enforcement actions, compliance assistance and cooperative programs have saved thousands of lives and prevented countless injuries and illnesses.

Although our task is far from complete, our progress gives us hope and confidence that OSHA will continue to make a lasting difference in the lives of our nation’s workers, their families and their communities.

Brayman Contruction Starts Bayfront Parkway Improvement Project in Erie

A Brayman and Trumbull joint venture project just celebrated the start of our Bayfront Parkway Improvement Project in Erie, PA.

“Construction will be completed in six phases over approximately four years. It will start at the Sassafras Street Extension intersection before the end of September and is expected to conclude with the construction of the pedestrian bridge at Holland Street.”

I-64 – July 2023 Update

Brayman Construction & Trumbull, A Joint Venture, is making headway on I-64 for West Virginia Department of Transportation. This project includes widening 5 miles of highway from two lanes into three lanes as well as constructing a new bridge over the Kanawha River.

Brayman Construction Earns Coveted ISNETWorld RAVS Plus Safety Recognition

Nationally Recognized Heavy Civil Contractor Demonstrates Commitment to Safety Excellence

Saxonburg, PA: Brayman Construction Corporation, a leading heavy civil and geotechnical contractor headquartered in Saxonburg, PA, has earned the prestigious ISNETWorld RAVS Plus Safety Recognition. This recognition demonstrates the company’s commitment to safety practices and risk management excellence.

Brayman Construction’s commitment to safety is critical to ensuring their employees’ well-being and their projects’ success. By prioritizing safety in their construction practices, Brayman Construction sets an example for the industry and helps to prevent accidents and injuries on job sites.

ISN is a global leader in helping hiring clients identify and manage contractors and suppliers that meet the customer’s safety and risk expectations. The ISN RAVS PLUS audit process is a deep-dive review and audit of a company’s written health and safety programs and how those programs are implemented. This process includes interviews with employees to assess their level of knowledge of and compliance with the company’s health and safety policies.

“I am incredibly proud of our team for earning the ISNETWorld RAVS Plus Safety Recognition,” said Stephen Muck, Chairman and CEO of Brayman Construction Corporation. “We will continue to prioritize safety in everything we do, and we remain committed to ensuring that all of our team members return home safely at the end of each day.”

“This recognition is a testament to our unwavering commitment to safety and our proactive approach to risk management. We have invested significant time and resources in developing and implementing robust safety programs and training initiatives, and this recognition from ISNETWorld affirms that our efforts are paying off,” said Angela Ravenscroft, Corporate Safety Director for Brayman Construction Corporation.

With this recognition, Brayman Construction has demonstrated its commitment to implementing and maintaining effective safety practices and risk management protocols, ensuring the safety of its workforce, and delivering quality construction projects to its clients.

Stephen Muck, Chairman and CEO, Named to 2023 Construction Power 100

“With the pandemic’s worst, most economy-crushing days in the rear-view mirror and the Build Back Better taps being turned on, it’s a good time to be part of Pennsylvania’s construction industry. From highway projects to skyscrapers, campus expansions to home renovations, there is no mistaking the power and presence of this rejuvenated sector.

The aggregation of accomplishment that follows highlights the influential contractors, architects, engineers, labor leaders, government officials and other experts who are responsible for Pennsylvania’s ever-evolving built environment.

The City & State 2023 Construction Power 100 was researched and written by City & State staff and freelance writer Hilary Danailova.”

Significant progress made on Grant Street Bridge construction

“Gov. Jim Justice announced the $10 million funding for a new bridge in October 2020 and the project was put on the “fast track” by the state Department of Transportation (WVDOT), which oversees the project.

But construction has been delayed numerous times as the company building the bridge, Brayman Construction, has had to work with WVDOT and Norfolk Southern railway to make sure the tracks below the bridge were clear when the bridge’s piers were being installed.

Pier work was finally completed a few months ago and the steel structure was then put into place, which for the most part freed Brayman to work on the bridge without interference with the railroad tracks below it.

The work is mostly on the deck of the bridge now, so no more delays are expected.”

Long road to completion 20 years in the making, Route 58 widening in final phase

Currently in Phase IV

“Phase IV, is a $55.7 million, three-mile project which includes widening Route 58 from Rhea Valley Road to the west corporate limits of Damascus. It is being paid for with federal highway funds. Work began in fall 2021 and includes construction of two matching bridges spanning the south fork of the Holston River and both are currently underway.

The contractor is Kanawha Stone Company of Nitro, W.Va., while the bridges are being built by subcontractor Brayman Construction based in Saxonburg, Pennsylvania, but which also operates a Wytheville office.

“We’ve built these bridges which are 474 feet long, 33 feet wide — two identical bridges that are steel span. The first deck pour [concrete] will be around April 1,” VDOT area construction engineer Brian Plummer said Thursday. “We’re roughly 95 feet off the water.”

The bridges are being built beside the current roadway. Once the first is completed, the plan is to shift traffic onto the bridge so workers can then modify the present intersections along the existing road.”Read the Full ArticleSource: Bristol Herald Courier

Spring Engineering Career Fair – Ohio University

Team Brayman recently attended the Spring Engineering Career Fair at Ohio University. The fair was filled with talented young Engineers from many different disciplines and backgrounds. We are looking forward to finding the right individuals to join the Brayman team.

The Assembly Pittsburgh Project

Congratulations Turner Construction on the The Assembly Pittsburgh project that earned The Master Builders’ Association of Western Pennsylvania Award for new construction over $25M. The Assembly was an old Ford Model-T manufacturing plant renovated to be the future home to University of Pittsburgh principal researchers focused on advancing knowledge and discoveries related to cancer biology and other areas. We appreciated the opportunity to be included on this project to assist with the deep foundation work.

University of Pitt Visitation

It was a pleasure having students from the University of Pittsburgh visit with us last Friday. We were able to give them an inside look into our internship and co-op programs, followed by an informal luncheon. It’s always great connecting with future professionals in the field!

If you or someone you know would like to learn more about these programs, go to: https://brayman.applicantpro.com/jobs/2210234.html

McKees Rocks Bridge To Close For Pavement Marking

The McKees Rocks Bridge will close for three hours Wednesday starting at noon.

Traffic will be detoured to the West End Bridge between noon and 3 p.m.

Work crews from Brayman Construction and Advantage Steel & Construction will close the bridge in both directions as they perform pavement marking.

Steel beams being placed for new Grant Street Bridge

Steel started “flying” Monday at the Grant Street Bridge in Bluefield as beams were hoisted into the air to be placed on the piers of the bridge.

Preparations were being made during the last few weeks to start placing the steel structure.

Kerry Stauffer, Bluefield City Engineer, said last week it was time for the steel portion of the bridge after the concrete support piers were in place.

Stauffer said the contractor, Brayman Construction, needed the large crane to place the steel, and also needed to work with Norfolk Southern Railroad to make sure some of the tracks underneath the bridge were clear for the work.

If all goes well, the bridge will be finished by August or September this year, he added.

A Backstage Tour of Charleroi Lock and Dam

Have you ever wondered what goes on behind the scenes of a jobsite? One of our projects Charleroi Locks and Dam got a backstage tour. Check out the feature on how the operations of this unique dam work.

Get in Touch

Interested in Partnering or Joining Our Team? Connect with us to explore opportunities for collaboration and career growth at Brayman Construction.